Start Your Fall Protection and Prevention Plan on the Right Foot

Editor’s note: This article was updated April 2022.

Why is a good fall protection and prevention plan so important?

OSHA violations related to slips, trips, and falls dominated the 2021 fiscal year. Indeed, a staggering 5,295 violations of Fall Protection – General Requirements occurred. This type of violation has now held the number one spot on the list of OSHA Top 10 Violations for the last 11 years.

There are four standards that aim to protect employees from harm caused by slips, trips, and falls. Fall Protection – General Requirements (1926.501), Fall Protection – Training Requirements (1926.503), Scaffolding (1926.451), and Ladders (1926.1053).

Well-thought-out fall protection and prevention plans align with the above standards to help reduce OSHA citations. Most importantly, having a good plan in place helps protect employees.

Can you afford the cost of a failed fall protection and prevention plan?

It’s important to recognize that although slips and trips seem like minor hazards, they can result in falls that could cause disability or even death. Yet there are other substantial costs to both the worker and your business that you should consider.

Potential costs of slips, trips, and falls for the employee:

- Lost wages

- Out-of-pocket expenses

- Pain

- Temporary or permanent disability

- Reduced quality of life

- Depression

- Death

Potential costs of slips, trips, and falls for the employer:

- Possible OSHA fines

- Potential litigation costs

- Loss of productivity & business

- Increased industrial insurance premiums

- Costs associated with training a replacement worker

Start by auditing your facility for slip, trip, and fall hazards

The first step in your fall protection and prevention plan should be to audit any building in which your business operates. Never assume that existing stairways or elevated surfaces are safe, compliant, or free from hazards. Identify structural vs. temporary hazards.

Temporary hazards include cluttered walkways and damaged surfaces. For example, things like boxes in an aisleway or cracks in the floor. These types of hazards should be attended to right away.

Take action to reduce structural slip, trip, and fall hazards

In contrast, structural fall hazards involve actual parts of the building. As a result, they may take more planning and resources to fix. Here are four structural fall hazards that should be a top priority to address in your fall protection and prevention program:

1) Cover drains

Always cover floor drains with grates in order to reduce the risk of slips, trips, and falls. Additionally, you must regularly inspect grate covers and supports for floor drains on walking-working surfaces to ensure that they meet standard strength and construction requirements.

2) Maintain proper aisle width & clearance

Aisles must be wide (and tall) enough for the intended use. This includes safe clearance for any mechanical equipment, for example, forklifts. Aisles that are too narrow can easily become obstructed or overcrowded increasing the risk of slips, trips, and falls.

3) Maintain stair safety

Slips, trips, and falls on stairs are especially dangerous, so your fall protection and prevention program should account for regular inspections to keep stairs in pristine condition. Treads and risers should be well-maintained with treads that have a slip-resistant surface. Additionally, handrails are all necessary for compliance and safety.

4) Safeguard elevated surfaces

Falls from elevated surfaces can result in some of the most serious workplace injuries. Elevated storage and walking-working surfaces must have a permanent means of access as well as physical controls including guardrails and toe boards.

Implement comprehensive fall safety training for all employees

The Fall Prevention Training Guide from OSHA is an indispensable resource for employers creating a fall protection and prevention program. It includes fall prevention guides for trainers and training materials such as videos, wallet cards, and worksheets in both English and Spanish.

The three main topics covered in the OSHA fall protection training guide include ladder safety, scaffold safety, and roofing work safety. It’s worth noting that ladder safety training is unique as it includes both inspecting the ladder as well as using and caring for the tool.

Show employees that fall protection is a priority for the company

The old adage “actions speak louder than words” is great to keep in mind when you want workers to take safety seriously. Conducting inspections, removing hazards, and training employees are all actions that send the message that you care about safety.

Another way to show employees that safety is a priority is to hold a Safety Stand-Down event. OSHA has dedicated May 2-6, 2022 as a National Safety Stand-Down with the goal of preventing falls in construction. However, you can hold a Safety Stand-Down any time.

Essentially, a Safety Stand-Down is time set aside to focus on the importance of fall protection and prevention safety. During such an event you can review protective measures, policies, and goals as well as encourage feedback from employees about fall hazards they may have identified.

Ensure workers have adequate PPE & fall protection supplies

As you create your fall protection and prevention program, you will need to consider Personal Protection Equipment (PPE) and other fall protection supplies. This includes employee training and managing company-issued PPE (for example tracking PPE with asset tags) as well as regular inspection and maintenance of PPE.

Set a routine for fall protection and prevention inspection and maintenance

It’s important that your fall protection and prevention plan includes regular inspection and maintenance. You should perform a facility inspection at least once a quarter. Walking-working surfaces should be inspected daily to ensure walkways are kept clear and floors are kept clean and dry.

Fall arrest systems and other fall protection PPE should be checked before every use. In line with OSHA standards for ladder safety, ladders should be inspected at a minimum of once before initial use at the start of every shift.

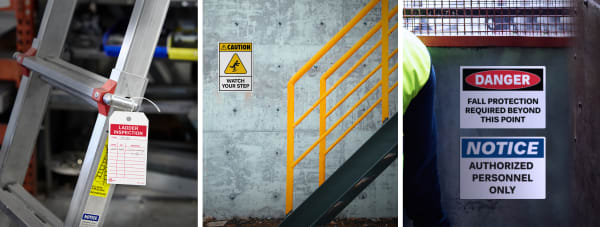

Ladders that do not pass an inspection must immediately be labeled “Dangerous Do Not Use” in accordance with 1910.145 and removed from service until repaired. OSHA-compliant ladder inspection tags and other safety tags (i.e. Do Not Use, Repair, Out of Service, etc.) are essential supplies for proper ladder inspection and maintenance.

Make sure you have OSHA/ANSI safety signs for fall prevention

Your plan should include strategies for addressing temporary slip, trip, and fall hazards quickly and efficiently. For example, consider a damaged floor that is causing a tripping hazard. The top priority is fixing the floor and removing the hazard, however, it will likely take time to accomplish.

In the meantime, it is crucial to be able to quickly block the hazard and mark it with OSHA/ANSI safety signage to alert employees. Printable adhesive safety signs are incredibly useful for helping to prevent slips, trips, and falls in such situations.

Maintain, review and update your fall protection and prevention plan

It’s normal for your fall protection and prevention plan to evolve over time in order to meet the needs of your facility. Not to mention updates made to keep up with state and local guidelines for workplace safety. Quick and efficient responses to slip, trip, and fall hazards are critical for helping employees work safely.

Plan to lead regular evaluations of your fall protection and prevention program to identify what’s working, what isn’t, and how to improve protocols. For access to hundreds of customizable OSHA/ANSI templates for fall protection and prevention safety, sign up for a free Avery Industrial account.

Please note, that the contents of this article and related articles on avery.com/industrial are for informational purposes only, are general in nature, and are not intended to and should not be relied upon or construed as a legal opinion or legal advice regarding any specific issue or factual circumstance.