Learn what printing service is best for your business

More articles you might like:

Today’s commercial printers produce everything from labels and magazines to catalogs, brochures, and direct mail advertisements. Digital printing and flexographic printing are the two main technologies used to print these items. As the industry evolves, and presses run at faster speeds, with an ever-growing choice of inks, substrates, and finishes, there are now many reasons a business might consider one printing method over the other. However, each method provides valuable advantages depending on the size of your business and your printing needs, and your company may have a need for one or the other or both.

In this article, we answer the question of what is digital printing and how is it different from flexo printing, and what is best for your business.

What is digital printing?

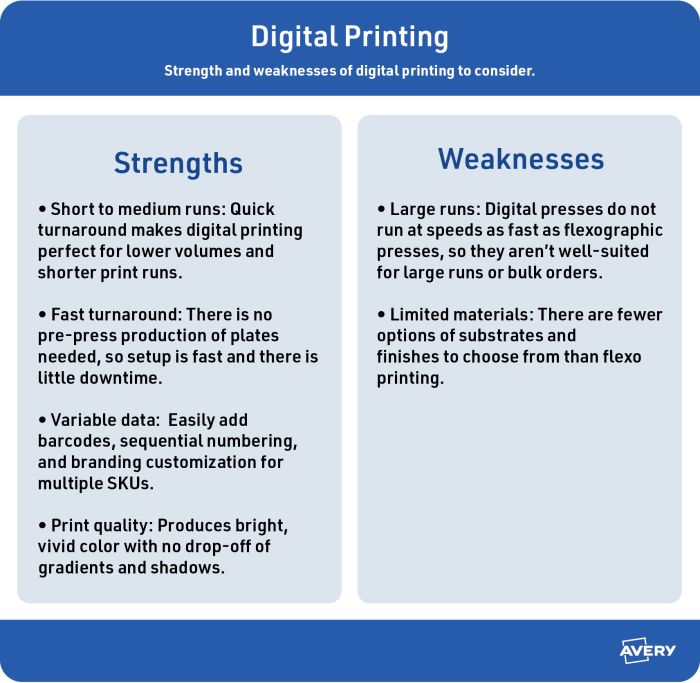

Digital printing, or industrial inkjet, is a method of printing from a digital-based image directly to a substrate using a laser or inkjet. Digital printing does not use printing plates, therefore, set-up, waste, and time spent printing are lower than traditional printing methods. In digital printing, the ink is sprayed or jetted directly onto the label substrate to print the required images and text.

This on-demand printing solution is suitable for short and medium runs. It’s also great for variable label printing. Variable printing is needed for things such as seasonal promotions, for producing labels for different product types, sizes, colors, or flavors, or even for personalization for customers. All of these options are just a few keystrokes away when you choose to use digital printing services.

Since digital printing does not require plates for different colors it’s a great choice for multi-colored labels as well as those that change regularly so that your company doesn’t need to invest in more plates for more colors.

What is flexographic printing?

Flexo printing, or flexography, is a high-quality label printing solution that uses rotary, in-line features. Each press has several printing stations that include flexible plates made of rubber or screen that are mounted to cylinders. The substrates pass through the stations where the inks transfer one color at a time, from the plate where the image is, onto the substrate.

For this printing method, each color requires its own custom-made plate. So there can be many plates needed for intricate designs, making them a less-than-ideal option for short runs due to the high cost. This technology is suitable for handling large-scale label printing and variable repeat lengths.

As the name implies, flexographic printing allows for flexibility with materials and techniques. If you need specialized materials, flexographic printing might be the right choice for you. While digital printing is catching up on the substrates and materials available, flexo printing still offers more.

Cost comparisons

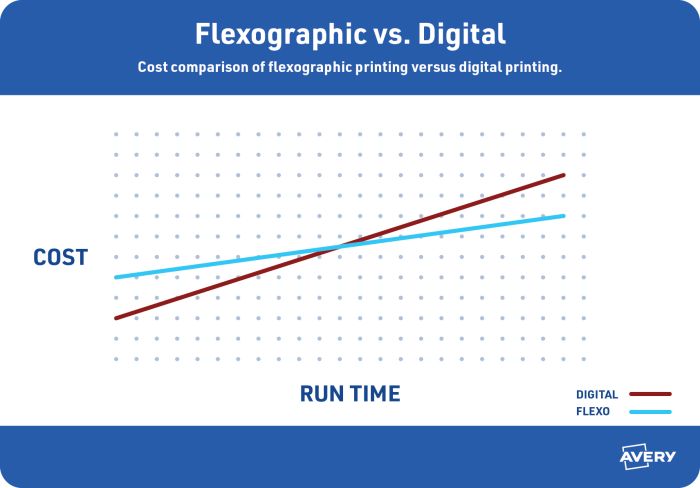

When deciding whether to use a digital printing service or flexography, it is important to consider several things. These include the size of the order, the label materials, and the number of colors and intricacies of the design.

For small- to medium-run label orders, it can be more cost-effective to outsource your label printing. You can try a dedicated digital printing service like Avery WePrint. We use industry-leading HP digital presses to create beautiful, full-color labels, stickers, cards, tags, and tickets.

If you do longer runs frequently, such as 10,000 labels or more, you might consider flexo printing. But talk to your printer or feel free to call our WePrint team at (800) 462-8379. We can connect you with one of our professional printing experts to discuss the best options available for your needs.