Label Laminate vs. Varnish

See what label coating is right for you

Other articles you might like:

Trying to decide what label coating you should add to your product labels can be confusing. In this article, we discuss varnish vs. laminate and what label coating is right for you.

While paper labels are great for many uses, they won’t hold up as well as those protected by a label coating. You should use a label laminate or varnish when you want to protect your printed label from exposure to moisture, abrasion, and light, as well as things like smudges and fingerprints.

Varnishes and laminates can also boost the visual appeal of your labels with a smoother, glossier finish. If you want a more natural look with texture and no shine then you should avoid a topcoat. However, if your label needs protection from the elements and you want to keep it looking good for a long time, then you should definitely consider a varnish or laminate.

So, what’s the right finish for you? Our Avery label experts have provided some insights into the difference between varnishes and laminates so you can decide what you need for your product labels or special project.

Varnish label coatings

Avery WePrint puts varnish over our custom printed labels to seal and protect the integrity of the ink and the label. Varnishes help safeguard against scuffs and abrasions. They also typically cost less than laminates, however, they don’t hold up as long.

The liquid varnish coating is available in glossy or matte finishes, and usually matches the underlying paper i.e., matte varnish for matte paper and glossy varnish for glossy paper. Matte varnishes provide a muted look on upscale products while glossy varnishes are shiny. However, they’re not as shiny as laminates.

Laminate label coatings

Laminates offer the ultimate label protection. The coating is available in a thin bi-oriented polypropylene film (BOPP) or Thermal Transfer (TT) polyester that is applied after the printing process to seal and protect the ink.

Laminates are ideal for labels that will be exposed to moisture, abrasion & light. We highly recommend them for products that are packed, shipped, or shelved. They’re great for items that face tough environments or that come in contact with oils or chemicals.

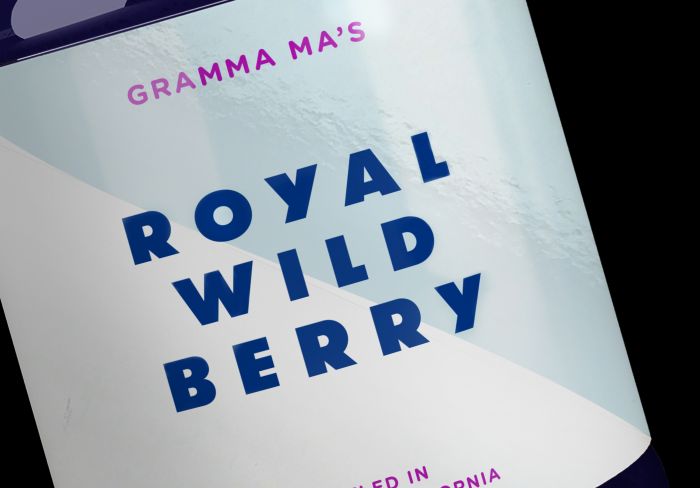

Laminates come in both glossy and matte finishes, as well as a thermal transfer for secondary printing. They’re great if you want a more pronounced sheen and texture than varnish. With a glossy laminate, you get a shiny, polished finish. On the other hand, matte lamination offers a smooth, no-glare finish.

If you’re still unsure what you should use for your product labels, please contact our Customer Care Team at 800-942-8379 for more information. We have a dedicated team to helping ensure you get the exact product and packaging labels you need.