How to Print on a Roll Labels Printer

A complete guide for printing roll labels from an inkjet printer

Other articles you might like:

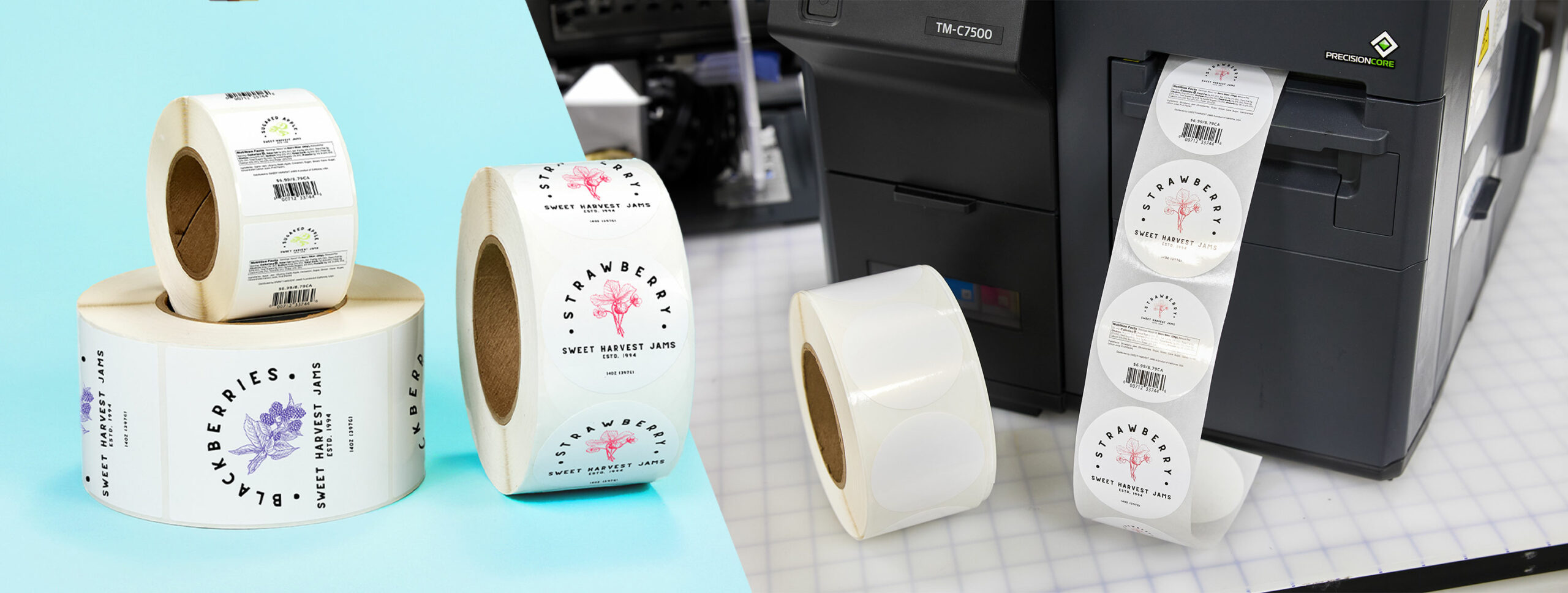

As a small business owner, efficient and cost-effective labeling solutions can have a significant impact on both your operations and branding. If you want to print your own roll labels using an inkjet roll label printer, we’ve put together this helpful step-by-step guide to help you understand and maximize your potential using this printing method.

We’ll give you insight into selecting the right materials, setting up your printer, and configuring your design software for optimal results. By following the steps below, you can achieve professional-looking labels that meet your specific needs.

1. Choose your printer

Selecting the right inkjet roll label printer can help you achieve high-quality results when printing product labels. Look for printers that offer advanced features such as

High-resolution printing: This will ensure that you get sharp, vibrant graphics for your labels.

Compatibility: Find a printer that’s compatibile with a variety of label materials and sizes. This is essential for allowing you to print on different types of media, from matte to glossy finishes.

Ease of use: Choose a printer with user-friendly interfaces and software integration for easy design and printing processes.

Another thing to consider is the printer’s speed. You want to make sure you find a printer that matches your production needs without compromising quality of the printing. And remember to buy from a company with reliable customer support and availability of replacement parts and inks so you don’t end up with a long delay in your business operations while waiting for parts or service.

While it can be tempting to go with a less expensive model, make sure to carefully select an inkjet roll label printer that meets your quality, speed, and versatility needs. By investing in the right printer, you will ultimately enhance your business’s efficiency and your products’ presentation.

2. Choose your labels

To achieve the best results from your inkjet roll label printer, choosing the right labels is just as important as buying the right printer. The type of label you use can significantly affect your print quality, durability, and overall appearance. You must also consider factors such as label size, material, adhesive, and compatibility with your printer to ensure seamless printing and professional-looking labels.

Label size

The size of your labels should be appropriate for the surface area of the products you’re labeling. Measure the dimensions of the product to determine the maximum and minimum label sizes that will fit.

Think about the amount of information you need to include on the label, such as branding, product name, ingredients, barcodes, and any regulatory information. Make sure you pick label sizes that can display all of this information clearly.

While standard label sizes are readily available and often more cost-effective, custom sizes may be necessary for unique product shapes or branding requirements. Assess whether a standard size meets your needs or if a custom label size is required for a perfect fit.

Label materials

The blank roll label material you choose affects not only the print quality but also your labels performance. Whether you need labels that can hold up in moisture, resist ripping and tearing, or present a sleek, glossy finish, understanding the different options available will help you make the right decision.

Paper roll labels are a popular choice for businesses due to their versatility, affordability, and ease of use. They’re ideal for a wide range of applications such as product labeling, shipping, and promotional materials. They usually come in with a matte or glossy finish, allowing you to choose the look that best fits your brand.

While popular, paper labels do have some disadvantages. They are less durable than synthetic labels. And they can easily tear, wrinkle, or get damaged when they’re exposed to moisture, heat, or rough handling. Paper roll labels also don’t perform well under extreme conditions. They are prone to smudging and fading when exposed to water, oils, or chemicals. The overall lifespan of paper labels is also shorter compared to synthetic options.

Printable synthetic roll labels are an excellent choice for businesses requiring durable, long-lasting labels. Made from materials such as polyester, polypropylene, and vinyl, these film labels are designed to be water-resistant, tear-proof, and resistant to chemicals and UV light. This makes them ideal for labeling products that will be exposed to moisture, heavy handling, or outdoor environments.

Synthetic labels are also known for their smooth surfaces, which provide beautiful print quality and sharpness. Available in matte and glossy finishes, synthetic labels offer a professional appearance that enhances brand image and product appeal.

There are a few disadvantages to synthetic labels. They are more expensive than paper labels and the higher initial cost may be a consideration for businesses with tight budgets. Also, not all inkjet roll printers are compatible with synthetic labels. Make sure the inkjet roll printer you choose is compatible with the specific type of labels you want to use.

3. Design your labels

To design your blank roll labels, use a software program that provides you with free tools to create the look you want. Ensure your design fits within the dimensions of the labels and includes any necessary bleed areas to account for slight misalignments during printing.

Avery Design & Print software is an easy way to design your labels online for free. You can simply upload your artwork into the appropriate template for your label size and the print. We also offer a huge library of pre-designed templates that you can customize. You can add things like text, images, logos, and barcodes. Avery also supports variable data, letting you create multiple labels with unique data, which is ideal for batch printing.

Besides Avery, there are several other free software programs available for designing roll labels that offer different features to suit various needs. Canva is a popular choice, known for its easy-to-use drag-and-drop interface and extensive library of templates, fonts, and graphics, making it ideal for creating visually appealing labels without any design experience. See how easy to create labels with Canva and Avery. A more advanced option is Inkscape, an open-source vector graphics editor. It offers design tools similar to Adobe Illustrator, allowing for precise and scalable label designs.

4. Set up your printer

To ensure smooth operation and optimal print quality make sure your thorougly read all the instructions. After unpacking your printer and all the components, follow the manufacturer’s instructions to install ink cartridges and ensure they are correctly seated. Then, load the roll labels into the printer, making sure the labels feed smoothly without jams or misalignment. Adjust the printer’s label guides to match the width of the roll labels and secure them in place. Finally, install any necessary printer drivers or software on your computer. Configure the printer settings to match the label size and materials you are using. Once you get everything set up, before printing an entire batch, print a test page to check the alignment, color accuracy, and overall quality of your labels. Make any necessary adjustments to the design or printer settings based on your test results.

5. Print

Afer running a test print and making any necessary adjustment to the printer settings or your label design, you’re ready to print. Make sure to monitor the printing process for any issues such as jams, misfeeds or misprints. You’ll want to stop the printer as soon as you see an error to keep from wasting a bunch of labels. And by monitoring the printing, you can ensure you’re getting consistent quality throughout the entire label batch.

Once you’ve finished printing, make sur to inspect your newly printed labels for quality control. Cut and separate the labels if necessary and properly store your printed labels to prevent any damage.

Conclusion

By carefully selecting the right printer and label materials, designing clear and creative labels, and setting up your printer correctly, you can achieve professional-quality labels from your home or warehouse.

Make sure to schedule regular printer maintenance and have an ongoing evaluation of your designs and materials to make sure your labels meet both the aesthetic you want and functionalality you need. This will not only streamline your label printing process but help you deliver products of the highest standard to your customers. With these steps in mind, businesses can confidently navigate the complexities of label printing, setting the stage for enhanced market presence and customer satisfaction.