Do You Need Durable Product Labels?

Estimated reading time: 7 minutes

See why long-lasting labels can make a difference in product packaging

Choosing the right labels for your products might seem simple at first—until you realize not all labels are built the same. Depending on what you’re selling and how it’s packaged, the difference between a standard paper label and a durable film label could mean the difference between crisp branding or ink that smears, labels that tear, or adhesive that peels too soon.

Your label needs to do more than just look good—it has to last. That’s why it’s important to think about both your packaging design and the conditions your labels will face. In this article, we’ll break down the benefits of durable labels, the rigorous testing Avery labels go through, and which types of products get the most out of them.

With nearly a century of innovation behind them, Avery knows that even small changes to label materials can make a big difference. Some durable labels are built to handle moisture, oils, sunlight, and even extreme temperatures. Others are flexible enough to stick to uniquely shaped or squeezable containers. And if you need industrial strength, there are even options tough enough to withstand 90 days in the ocean.

Not sure if durable labels are right for your products? Keep reading—we’ll help you decide.

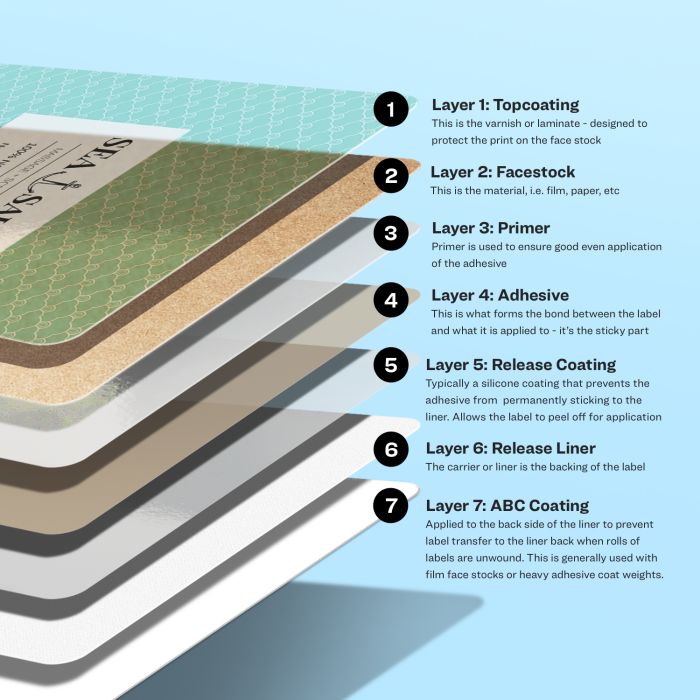

What makes up a label?

Labels are made in many layers. The main three layers are the face stock, the adhesive, and the liner.

The face stock is the front of your label, the part your customers will see. The adhesive is the glue that sticks to your packaging and can be permanent or removable, and the liner is the paper backing you remove from your label right before application.

Face stock: Standard labels are made with paper face stock. It can be a more substantial, premium paper but paper labels have their limitations. Durable labels have face stock made from plastic films like polyester (PET), polypropylene (BOPP), and other synthetics to resist tearing, moisture, chemicals, and more.

Adhesive: The adhesive on standard paper labels is generally made for light, indoor use. While the adhesive on many durable labels will stay adhered in harsh environments, even on many removable labels.

Liner: The label liner is the backing paper that supports the label through manufacturing and protects the adhesive until you apply it to your products.

Topcoat: Durable labels feature a surface coating that increases ink adhesion with both standard and digital print technologies.

Avery uses only the highest quality face stocks, adhesives, liners, and topcoats when manufacturing its labels. And all Avery labels are rigorously tested at industry-accepted standards or higher. Just a few of the tests the labels go through include tensile strength, 90-degree peel adhesion, Taber® abrasion, and chemical resistance. All of the labels are also put through real-life adhesion and application testing.

Why these tests are important

Tensile strength: Tensile test machines measure the pounds of force you need to break a label. Durable labels have much higher tensile strength than standard paper labels making them more resistant to ripping and tearing.

90-degree peel adhesion: Tensile testing machines pull labels at exactly 90 degrees from a variety of surfaces to measure the pounds of force they need for removal.

Taber® abrasion: Taber abrasion machines are the industry standard for testing resistance to scratching, scraping, and rubbing. Avery durable labels are abrasion-resistant to preserve print integrity and keep the labels readable to both humans and barcode scanners.

Chemical resistance: Avery durable labels must also pass chemical resistance tests such as heptane, HCL 37%, and pH3 buffer. We also test against common cleaning solutions like Windex, 409, and isopropyl alcohol.

Adhesion testing

Avery labels are not only tested for their durability but also for their ability to adhere to certain containers and in specific conditions.

We conduct adhesive performance tests in a variety of different real-life extreme conditions. From the hot, dry environments of Arizona to the moist conditions in Florida, we test our labels to make sure they’ll stick no matter where you live.

Avery also tests our labels for their ability to adhere to difficult surfaces.

- Contoured containers – Small cylindrical bottles, pens, pencils

- Plastics – Storage containers

- Textured plastics -Heavy-duty storage bins

- Irregular surfaces – Plastic bags with items inside, recycled paper to-go bags, take-out containers

Real-life application testing

Avery puts its labels through actual in-use testing to ensure they will work in the conditions they were meant for.

Some examples of testing done are:

- Security seals – Evaluate adhesion on surfaces with moisture condensation replicating application to cold drinks.

- Soap and candle labels – Evaluate adhesion on containers with candles lit to ensure the label adhesive sticks and stays on hot surfaces.

- Hand sanitizers – Evaluate label construction to ensure print and graphics stay vibrant and resist a variety of commercial hand sanitizers

- Safety signs – Analyze print durability against a variety of splashes from water and cleaning solutions.

- Floor decals – Evaluate adhesion on a variety of commercial flooring types from marble and porcelain to tiles with texture. The impact of floor cleaners was also tested.

Label application tips

- Clean your container surface so it’s free of contaminants (e.g. oils, liquid, moisture condensation, powder, dust)

- Do not apply labels if the surface temperature is below 30°F at the time of application

- Make sure your product surface is relatively uniform and flat

Recommended uses for durable labels

Avery durable labels will work great as a permanent labeling solution for almost any application. Some popular applications listed below can benefit from durable labels, as well as many others. If you don’t see your product listed below or want some help picking the right label, please call our Customer Care team at (800) 942-8379. They’ll be happy to help you pick the correct label for your project.

Health & beauty products

Men’s grooming, essential oils, face serums, shampoos & conditioners, cosmetics, liquid soaps, lip balms, body butters, lotions, creams, deodorants, oral care, hair gels, mousses, candles

Food and drinks

Condiments, sauces, jam, honey, marinade, frozen foods, bakery items, snack food, candy, spices, barcodes, coffee, tea, juice, water, beer, wine, hard liquors, craft brews

Wellness

Supplements, vitamins, CBD products, medical marijuana, cartridges, tinctures, edibles, topicals, concentrates

Outdoor applications

Flower pots, fertilizers, gardening products, pet supplies, household cleaners, automotive products

What durable labels are right for you?

Avery offers a variety of durable labels for products and packaging. Whether you want to order thousands of custom printed labels on a roll or just a few label sheets, we have a solution.

Avery custom labels offer the widest variety of materials, finishes, and formats of durable labels. Everything from clear film and squeezable labels to sleek metallics and thermal transfer labels is available to customize and order online.

If you want to print your durable labels yourself, Avery offers two options. You can choose from waterproof film labels or two clear film labels in your size, shape, and quantity or you can also buy several varieties of Avery packaged durable labels in-store or online.

Remember, if you have any questions, please feel free to contact us by phone or chat. We are here to help!