Thermal Printers: Direct Thermal vs. Thermal Transfer Labels

Estimated reading time: 8 minutes

See what type of thermal printer is best for your business

Other articles you might like:

Thermal printers have many practical uses for many businesses, especially on the order fulfillment side of operations. Thermal printing is a reliable method that produces high-quality graphics and text. The printers are popular for their ease of use, quick speed, and overall efficiency.

The two types of thermal printing are direct thermal and thermal transfer. This article will detail thermal printers and the differences between direct thermal printing and thermal transfer printing. We will also discuss the pros and cons of each, and what solutions they can offer your business.

Once you decide on the best fit for your business, you can order both types of labels from Avery. We offer direct thermal labels, including industrial direct thermal labels and standard direct thermal labels for a variety of thermal printers including Seiko Smart Label Printer®, DYMO LabelWriter®, and Zebra® printers. You can also create and order custom printed “shell” labels and print your variable data or compliance information using your existing thermal transfer printer.

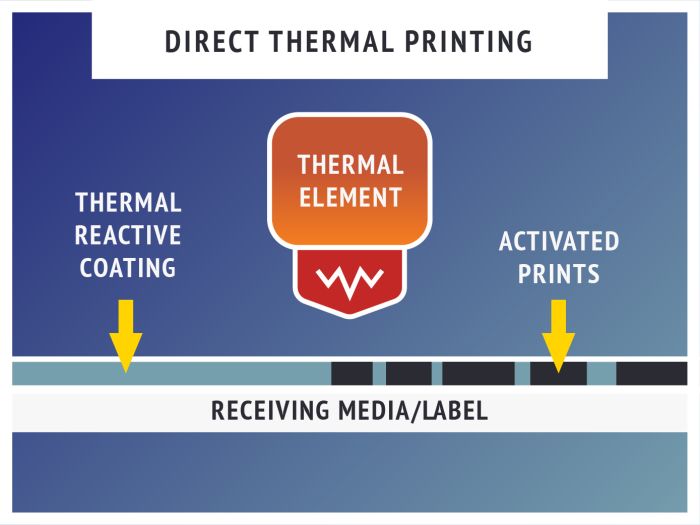

What is direct thermal printing?

Direct thermal printers are a practical choice for many businesses, and the printers are often the less expensive of the two options. Direct thermal printing applies heat directly to a specially treated label material that has ink set in the material. When the print head comes into contact with the label, the heat transfers and then cools, providing the user with clearly printed text or imagery.

Typically, direct thermal printers are small and feed out printed labels on a roll. They can be used with a variety of desktop and mobile printers as well as industrial units. They are best for indoor labels or short-term labeling projects.

Pros

Direct thermal printing is easier to use than a standard printer since they don’t require toner, ink cartridges, or ribbons. So this means fewer supplies to purchase and you will never run out of ink or toner in the middle of a job. When your company is handling high order volumes, holiday rushes, and even normal operations, that’s an enormous help in productivity.

Direct thermal printing machines also tend to be cost-effective. Small units run around $1,000, while more sophisticated industrial models run under $10,000. Additionally, direct thermal printers should have minimal maintenance. This is due to the small number of moving pieces, which in turn means the printers run longer. The only thing you’ll need to do is turn the machine on and change out the label rolls as needed.

Cons

Due to the heat sensitivity of the label material, direct thermal printing is not recommended for any high-contact applications or long-term labeling solutions. In addition, anything direct thermal printed is also susceptible to damage from liquids and chemicals.

Also, direct thermal printers can only produce black and white images due to the treatments on the label paper. While this is not a problem for barcodes or shipping labels, typically, that rules out direct thermal printing for other types of labels.

Additionally, your company will need to find a way to ensure debris does not enter the machine. If it ends up between the printer head and your labels, not only will there be blank spots in your labels, but it can damage the printer head permanently, so your company will spend more replacing them.

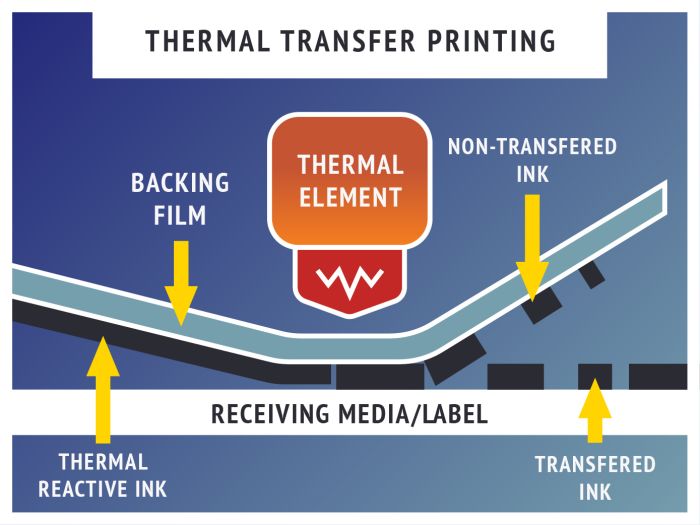

What is thermal transfer printing?

Thermal transfer printers are a unique process similar to direct thermal printing. It involves a thermal element, a ribbon with transfer ink, and a label roll. The thermal element interacts with the ribbon, which transfers the script or image to the labels. Typically, the label rolls are specially treated to take the ink, leading to a crisp finish.

The ribbon serves multiple functions in thermal transfer printing, from coloration to extending the life of the print head. Thermal transfer printers do tend to be a little bigger to accommodate the extra parts but are still not too large to place on a shelf or counter.

Avery custom printed labels with thermal transfer printable laminate is compatible with thermal transfer ribbons such as Armor AXR-7+, iimak SP 330, ITW B324, DNP R300, Sato SDR-A, and Zebra 5095. The industrial-strength labels feature permanent adhesive and are waterproof & resistant to chemicals, abrasion, UV, and tearing.

Pros

Due to the nature of the material treatments, thermal transfer printing is generally durable. Labels can last six months or more and do not fade over time. Typically, the label rolls are even available in weatherproof variations.

Generally, thermal transfer printing offers greater material compatibility as well. For example, where direct thermal printing uses a single variety of labels, thermal transfer printing often works with several materials your company can purchase from a reputable label supplier.

Another advantage of thermal transfer printing is the option to print in color. Unfortunately, the color from the ribbon applies to the entire label, so your company can only add one color. However, this trait can be used with great efficacy with a bit of creativity.

Most ribbon designs for thermal transfer printers include a buffer layer that’s placed against the printer head. This design reduces the wear on the head so that each one lasts longer. There will also be fewer hiccups as your company operates the unit.

Cons

The disadvantages of thermal transfer printing typically relate to the ribbon. Thermal transfer printers need a supply of ribbons to replace used ones, which can add up. Thermal transfer printers are also more expensive than direct thermal models initially.

Another disadvantage is the green aspect of these printers. While ribbons can last a long time, they are still generally a poly-based product made in part from crude oil. If your company values environmental responsibility, it may be worth evaluating whether thermal transfer printing is the best solution.

When to use thermal printing

Both varieties of thermal printing work well in certain conditions. Generally, direct thermal printing is best for short-term label needs. Thermal transfer printing tends to work best for long-term labeling needs.

Shipping & addressing

If your company ships directly to customers, you need daily shipping labels. Most shipping takes place over a few days or weeks, and generally, the boxes are rarely handled. Additionally, most shipping boxes don’t see extreme conditions. Instead, shipping is often machinery-driven when it’s not in a truck or container, limiting the opportunities to smudge the label. That makes direct thermal printing a good candidate for shipping.

If your company is a B2B supplier or has large D2C orders, you may need pallet or container shipping. Your labels potentially could be stacked or placed outside for an extended period, which makes thermal transfer the best choice. There are completely weatherproof labels available that are compatible with thermal transfer, though even the non-weatherproof versions have solid durability.

Barcodes & inventory tracking

Businesses use barcodes for tracking, inventory, sales, and more. For product barcodes, direct thermal is often the best choice. This option ensures readable barcodes at a reasonable price. Direct thermal is frequently the choice for barcodes due to their efficiency and legibility. Avery also offers a free barcode generator to help you easily create barcode labels.

Durable labeling is key for inventory tracking, especially if you store items for an extended period. If everything moves quickly through your facility, direct thermal is a practical choice. However, thermal transfer printing is a better option if items are stored, frequently moved, around chemicals, or in extreme temperatures.

GHS labeling

The Globally Harmonized System (GHS) for the classification and warnings on chemical labels is an international standard to make sure everyone involved in the manufacturing, transportation, usage, and disposal of hazardous chemicals understands the dangers they may face.

If your company has to adhere to GHS labeling requirements, Avery offers custom printed labels with thermal transfer printable laminate. You can create shell labels with custom information and run them through your thermal printer to add specific data. The labels are waterproof and resistant to chemicals, abrasion, UV, tearing, and harsh temperatures. thermal transfer printers.

Receipts

Receipts, especially in fast-moving industries, are often used in the order fulfillment process. For example, it’s common to see them used in anything related to food. However, since the receipts don’t need to last long, direct transfer printing is a good choice. Direct transfer creates practical receipts that are easy to handle throughout the fulfillment process. The compact units are generally easy to place and require little consideration to deliver maximum convenience.

Now what?

Choosing a direct transfer printer or thermal transfer printer for your business is a significant decision. Picking the right option for your company’s specific situation can make an enormous difference in production. For any questions about the labels needed for your printer please call our Customer Care Team at (800) 942-8379. They will be happy to assist you with any of your label questions.