What is lockout tagout?

“Lockout tagout” is a set of procedures for de-energizing machines and equipment so that they don’t accidentally turn on. These steps are important so that workers can safely carry out repairs or maintenance. Chiefly, the lockout part involves physically closing electric circuits and valves, securing moving parts, etc. Meanwhile, workers use tagout to communicate that no one should turn energized equipment back on until an authorized employee deems it safe to do so.

Additionally, “lockout tagout” is just one way to name or refer to these steps. You may see these steps interchangeably referred to or written as “LOTO,” “lockout/tagout,” or “lock out tag out.” In this article, we’re sharing tips and free lockout tag templates to help you better practice LOTO safety.

Lockout tagout procedure (step by step)

Why is lockout tagout important

Most importantly, controlling hazardous energy is necessary to protect workers from serious injury and death. Specific energy hazards include electrocution, burns, lacerations, amputations, and/or crushed or fractured body parts from machinery. Any workplace with machinery that stores energy is required to practice LOTO safety. What’s more, LOTO safety is enforced by OSHA under OSHA Standard 1910.147 (commonly referred to as the lockout/tagout standard). Indeed, OSHA non-compliance penalties are quite stiff. They range from $16,131 per violation to $16,131 per day beyond the abatement date, up to $161,323 per violation.

OSHA standard for lockout tagout

Part 1910.147(c)(5) of the lockout/tagout standard covers specific rules for both locks and LOTO tags:

- The employer must provide locks, LOTO tags, and all other hardware for isolating, securing, or blocking machines (for example, chains, wedges, etc.).

- Singular use. You must only use locks and LOTO tags for lockout/tagout procedures.

- Durability. Locks and LOTO tags must be durable enough to last through lockout/tagout procedures.

- Standardization. Locks and LOTO tags should be uniform in color, shape, or size within a facility.

- Identification. You must identify the authorized employee who applied the locks and LOTO tags on both devices.

7 important LOTO safety tips

1) Brush up on the specific OSHA requirements for LOTO tags

LOTO tag OSHA requirements differ from lock requirements because the material durability, print stability, and way they attach to equipment are all regulated. Here are the specific rules for LOTO tags that you must follow in order to achieve OSHA compliance:

- Attachment. Nylon cable ties (zip ties) are the preferred method for LOTO tag attachment. Alternatives must be non-reusable, hand-attachable, self-locking, and withstand at least 50 pounds of pull force.

- Pull strength. LOTO tags must possess a tensile strength capable of withstanding a minimum pull force of 50 pounds. This requirement applies to the tag material itself as well as the chosen attachment method.

- Print stability. LOTO tags must remain intact, and the print must remain legible in wet, damp, and corrosive environments.

- Hazardous warnings. The warnings on LOTO tags must have a legend that describes the warning.

- Standardized print/format. You must standardize the print and format of LOTO tag headers and information. In general, we recommend using OSHA/ANSI warning colors, formatting, and headers.

2) Make sure you know when LOTO is required

To ensure worker safety during maintenance or repair, OSHA mandates LOTO procedures for any equipment with stored energy (thermal, electrical, chemical, pressurized, etc.). This includes tasks like cleaning, repairing, or even unjamming. Following the six steps outlined in OSHA Standard 1910.147(c)(4) ensures proper lockout/tagout before work begins and safe release upon completion.

3) Understand the differences between lockout and tagout

While most people refer to lockout and tagout procedures as one complete set of steps, they are also individual actions within the system of procedures. For instance, lockout (LO) means physically placing a lock on an energy isolation device. In contrast, tagout (TO) is a visual warning system. It tells others that it is not safe to operate tagged machinery until the tag is removed. Practicing all the LOTO steps together is the best way you can protect workers from hazardous energy.

4) Know where to apply LOTO tags

In short, you should always place LOTO tags on the controls an employee would use to energize machinery or equipment. The same goes for any other visual warnings. In fact, this is a direct quote from a Cal/OSHA online resource for lockout-tagout:

“Accident prevention signs or tags or both must be placed on the controls of the power source of the machinery or equipment.”

Cal/OSHA eTool for employers

5) Be clear about who can remove lockout tagout

Only authorized employees can remove lockout and tagout energy controls. Period. However, this can be confusing because OSHA 1910.147(c) requires three different types of employees that need lockout and tagout training. These are: (1) authorized, (2) affected, and (3) other. The types of training required for each type of employee are basically a tiered system based on the impact of and proximity to equipment and machines that store energy.

6) Identify employees that require LOTO training

Authorized employees are workers specially trained to safely apply, use, and remove energy controls for lockout-tagout procedures. Affected employees are normally the people who operate the machine or piece of equipment that is under lockout or tagout. However, they may also be employees whose job requires them to work in the area where service or maintenance on such machines is happening.

Be aware that an affected and authorized employee can be the same person. This happens when the person who normally operates the machine or equipment is also the person who performs servicing or maintenance.

Don’t discount “other” employees

OSHA classifies anyone else who may be working in an area where LOTO procedures are used as “other.” Even if these workers are not directly involved in LOTO procedures, employers must still train them on the procedures. Above all, “other” employees must be trained to understand that it is never okay to re-energize or restart equipment or machinery that is locked out or tagged out.

7) Standardize your lockout tags

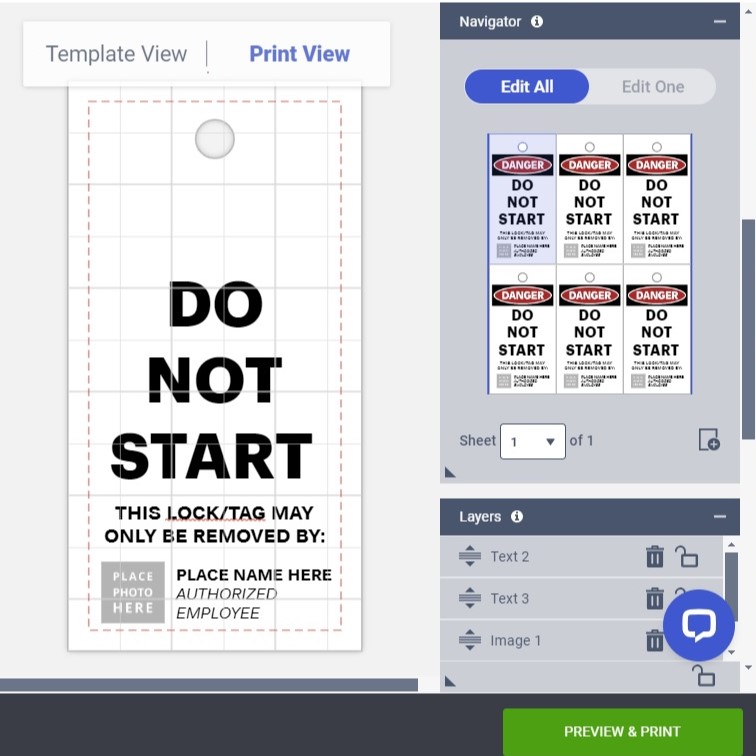

You need to standardize your LOTO tags because it is an OSHA requirement. However, standardization increases safety in several key ways. Firstly, it helps employees identify locked-out machinery and comply with hazard warnings, even if they’re not trained in lockout/tagout procedures. Furthermore, creating custom LOTO tags with printable plastic tags and free online software ensures accurate information. Additionally, you can add photos of authorized employees to make it easy to identify who can remove tags.

Best printable lockout/tagout tags

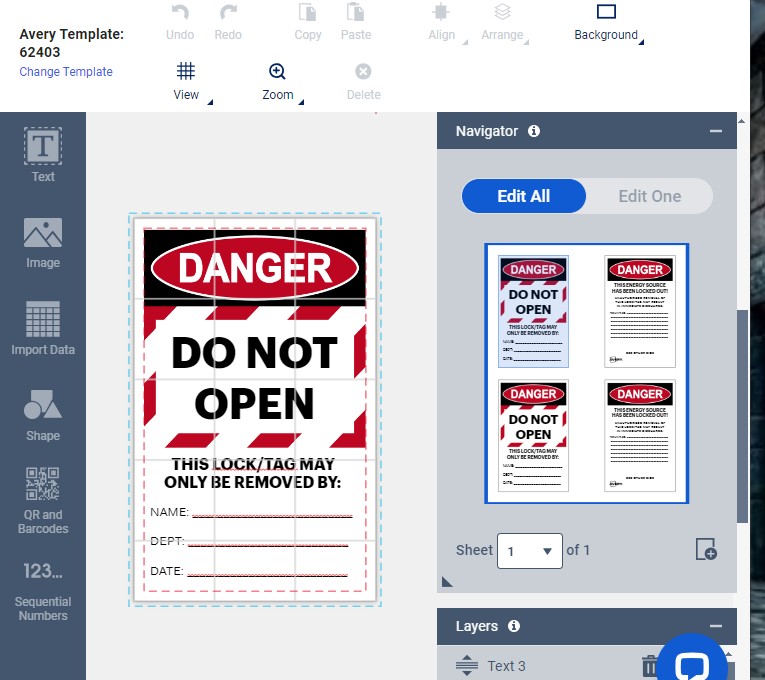

Avery printable, plastic safety tags provide a versatile and compliant solution for your lockout/tagout needs. Firstly, the durable plastic meets OSHA safety regulations for strength and can withstand up to 50 pounds of pull force. Moreover, they’re made from 11-mil plastic that resists tearing, chemicals, UV damage, and abrasion for up to two years outdoors. Lastly, the design options offer maximum flexibility.

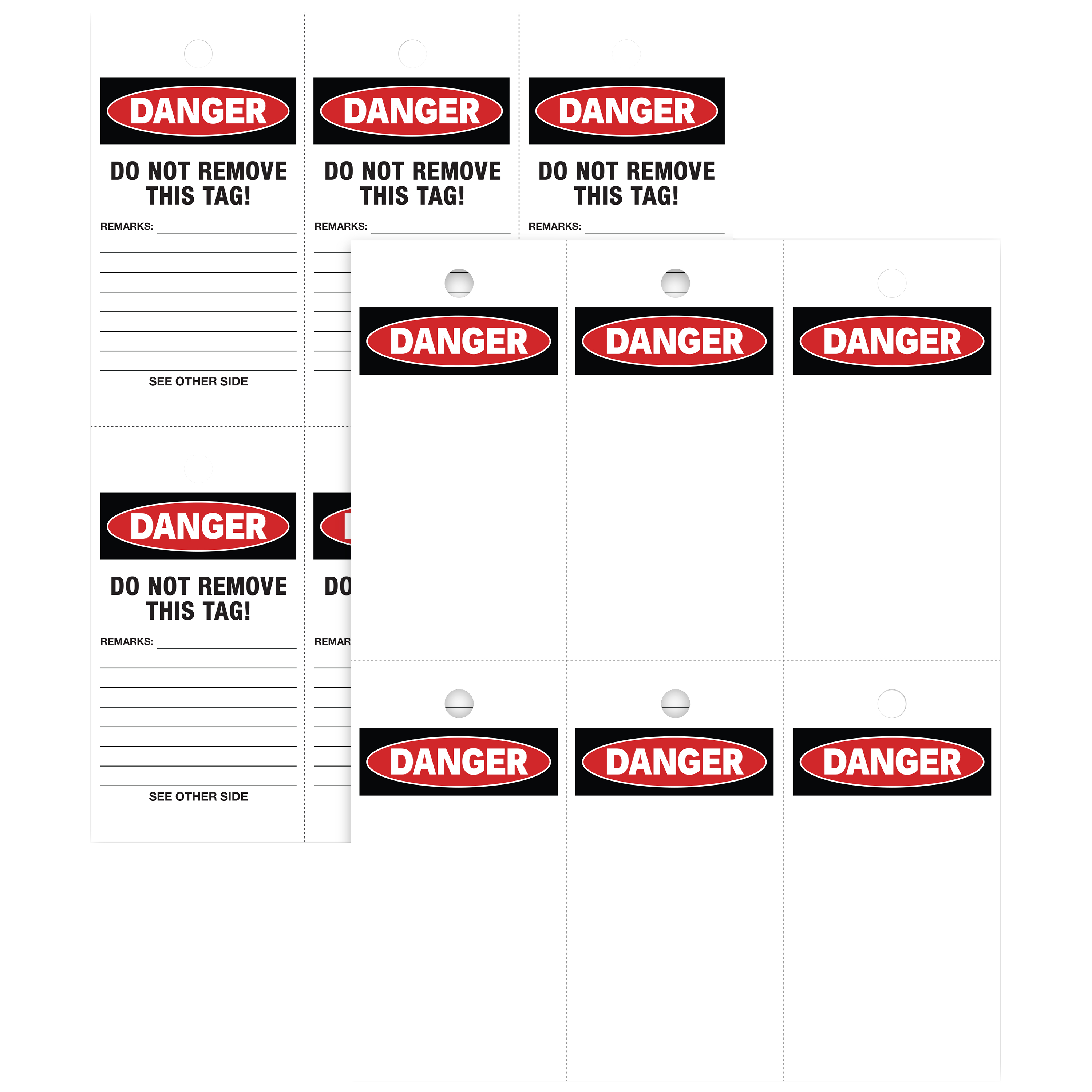

Need a clear warning tag without a color printer? Choose preprinted DANGER tags. These double-sided tags feature a bold DANGER header, leaving one side blank for custom information.

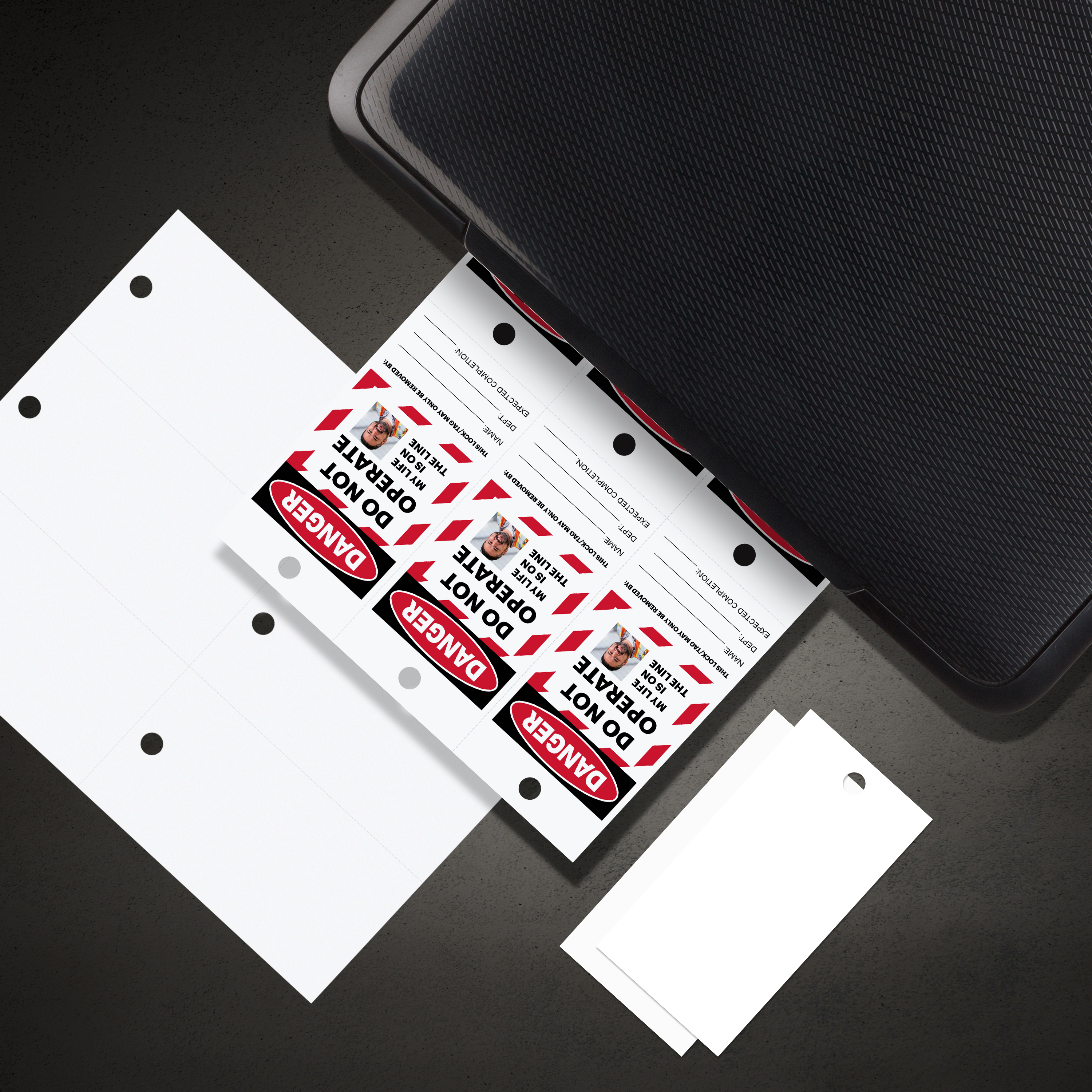

You can print on these plastic tags using any standard desktop laser printer.

Choose blank white tags to add the lockout/tagout design of your choice.

You can print your own plastic LOTO tags on these using any standard color laser printer.

Lockout/tagout tag examples

“Tagout devices shall warn against hazardous conditions if the machine or equipment is energized and shall include a legend such as the following: Do Not Start, Do Not Open, Do Not Close, Do Not Energize, Do Not Operate.”

OSHA, 1910.147(c)(5)(iii)

“Do Not Start” lockout tags clearly warn workers that a machine is under service and must not be started.

Customize this design, then print on Avery 62401 tags with a preprinted DANGER header.

Use “Do Not Open” tags to caution against opening valves or other access points during equipment maintenance.

Customize this design, then print on Avery 62401 tags with a preprinted DANGER header.

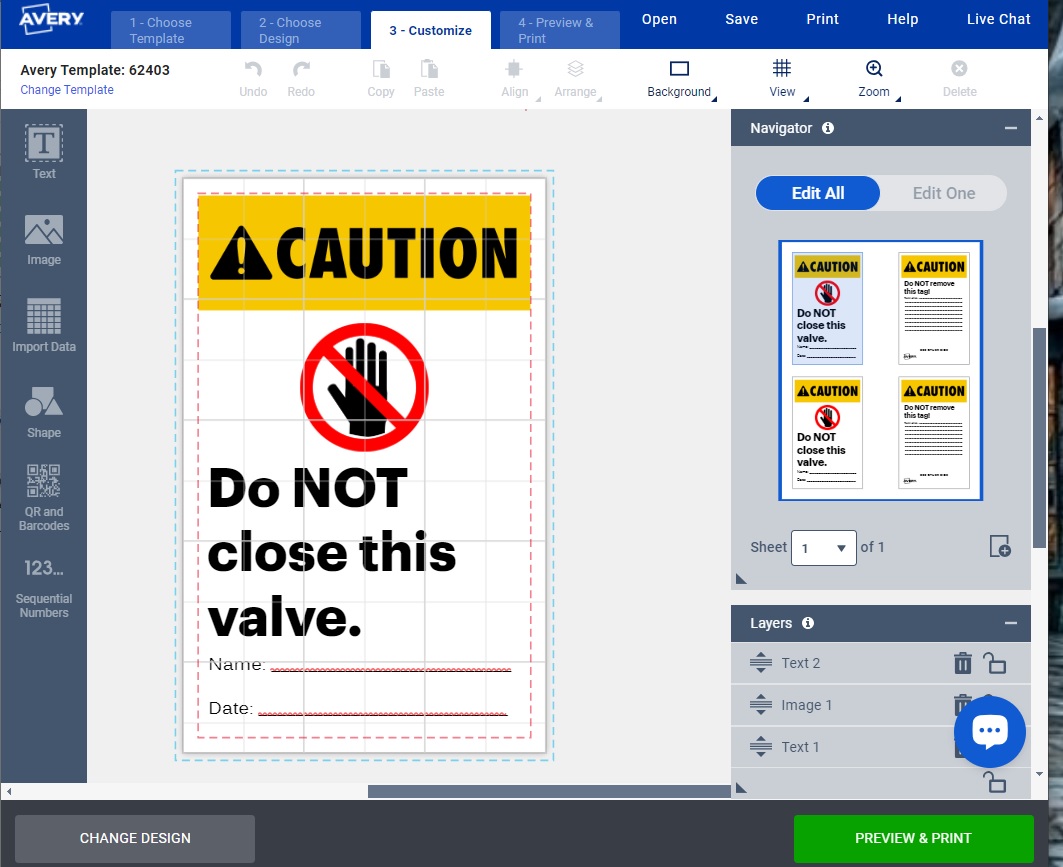

Use a “Do Not Close” tag like this one to caution against closing valves during equipment maintenance to prevent pressure buildup.

Customize this design, then print on Avery 62400 tags with a preprinted DANGER header.

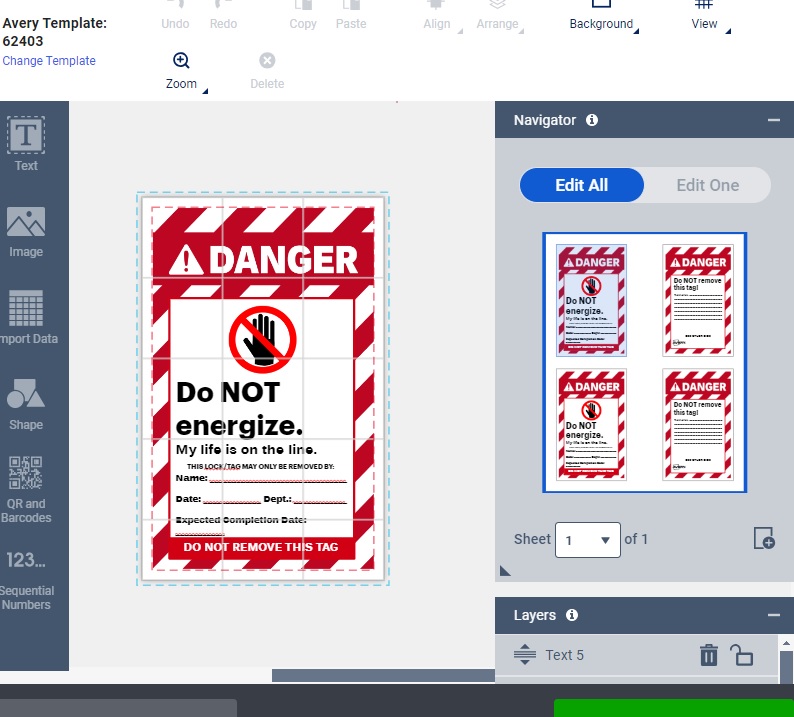

“Do Not Energize” tags help prevent accidents by cautioning against powering machines during service.

Customize this design, then print on Avery 62400 tags with a preprinted DANGER header.

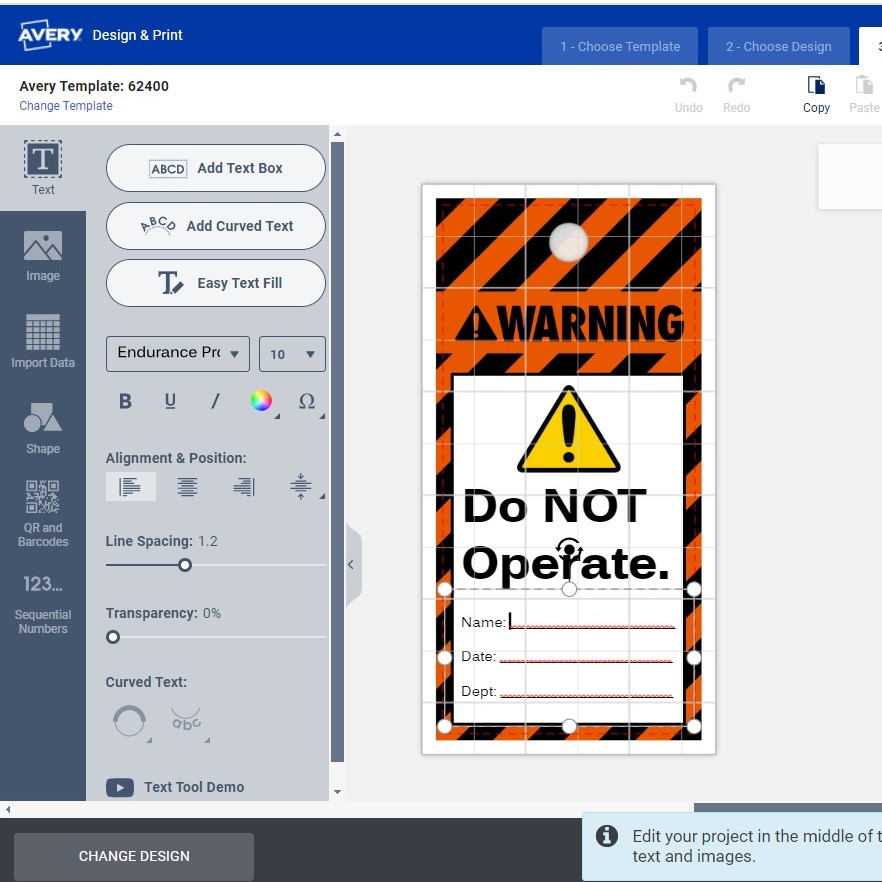

A “Do Not Operate” LOTO tag signals machinery should not be used to prevent injury or death from uncontrolled energy.

Customize this design, then print on Avery 62400 tags with a preprinted DANGER header.

What is LOTO and how to do it better

In summary, Lockout Tagout (LOTO) is a set of procedures to ensure worker safety during machinery maintenance.

- What it is: LOTO involves shutting down and isolating machines to prevent accidental startup. Locks and tags are used to physically block energy sources and visually warn others not to operate the equipment.

- Why it’s important: Lockout/tagout protects workers from serious injuries caused by hazardous energy like electricity, chemicals, or pressure. OSHA mandates LOTO in workplaces with such equipment.

- How to implement LOTO: Review OSHA regulations and best practices for lockout/tagout, including tag requirements, when to use LOTO, and employee training.

- Standardization and resources: Standardizing LOTO tags improves safety and compliance. Avery printable plastic tags and our free resources (such as free templates and free online software) make it easier for you to customize LOTO tags.

Please note that the contents of this article and related articles on avery.com/industrial are for informational purposes only, are general in nature, and are not intended to be relied upon or construed as a legal opinion or legal advice regarding any specific issue or factual circumstance.